Quick Disconnect Fittings in Brewing: A Comprehensive Guide

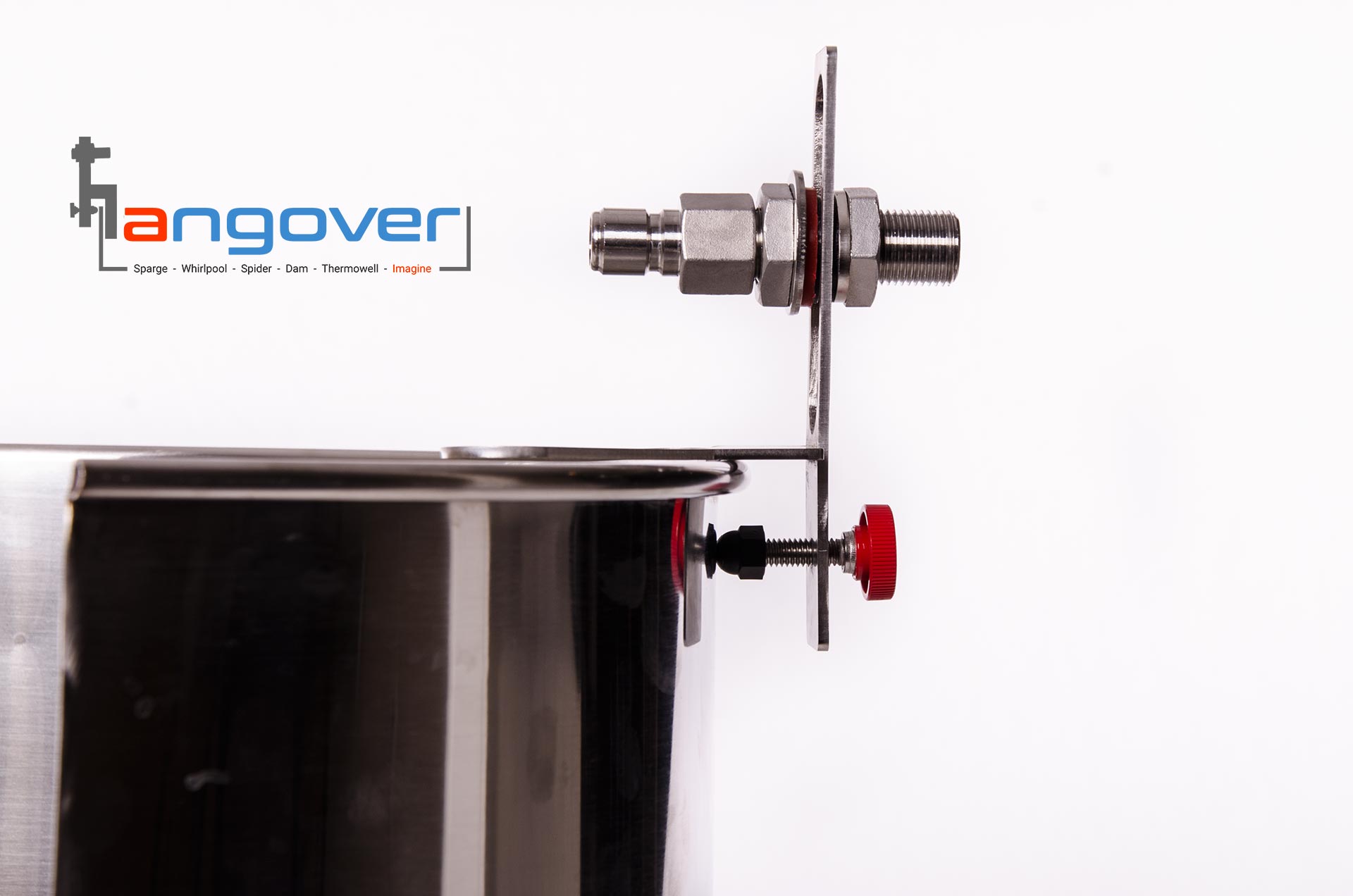

While professional breweries already use them, quick disconnect (QD) fittings are a game-changer for home brewers, embodying simplicity and efficiency during your brew day. These fittings, which allow for the rapid connection and disconnection of liquid lines without tools, have helped streamline the brewing process, making them an indispensable asset and time saver on brew day. This guide aims to be a definitive source for understanding and utilizing QD fittings in brewery, covering their types, applications, benefits, and maintenance. Introduction to Quick Disconnect Fittings At their core, Quick Disconnect fittings are designed to simplify the fluid transfer process, enabling swift Read More